One of our principal values is to drive industry and academic collaborations to advance innovation to the benefit of both the business and research communities and wider society. One such effective partnership is with the University of Warwick with a current project to optimise wind energy using the power of CFD simulation and AI.

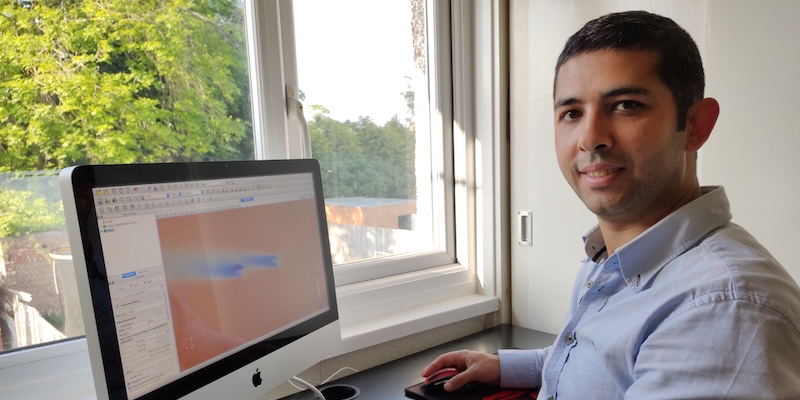

As part of this research, Muhammed Nedim Sogut has just successfully completed the first year of his PhD, Machine Learning in Wind Farm Modelling based on Computational Fluid Dynamics, under supervision of Dr Peter Brommer. Zenotech’s co-founder and director, David Standingford, is co-supervising the doctorate.

This PhD project arose through an industry study group on uncertainty quantification and management in 2017, which Zenotech participated in, along with three other companies, addressing wind energy modelling problems. With an MSc on renewable energy technologies behind him, Muhammed was keen to explore the area further with a doctorate and sought David’s expertise as co-supervisor.

With the switch to renewable energy, modelling wind farms is essential both during the planning and operation stages in order to maximise power output and predict maintenance levels. However, current models of sufficient quality are computationally costly. This project is part of the vital collaboration between industry and academia to investigate ways of reducing this cost using machine learning (ML) techniques.

The research involves running high-fidelity computational fluid dynamics (CFD) simulations of wind farms at various scales. Then, this data will be used to parametrise a surrogate model based on machine learning techniques, such as Artificial Neural Networks (ANNs).

The research utilises Zenotech’s CFD solver, zCFD, which offers affordable computational fluid dynamics at scale. At the end of the first year, the project is progressing well. Muhammed told us:

“We began with digging deep to figure out turbulence between two turbines for various spacing, wind angles and wind speeds. In particular, we defined the angle of independence (the angle of wind where two turbines will not affect each other after 0 degrees).

“A simulation has been created using zCFD, Zenotech’s CFD solver, in the following circumstances: a wind farm with two turbines from three to seven diameters spacing for changing wind direction of 15 degrees on both sides at 10, 12 and 14 m/s wind speeds In my first year, the angle of independence for changing wind direction, speed and distance between turbines has been investigated, the data required to train an ANN has been created and the individual effects of wind speed, wind direction and spacing between turbines have been examined.”

The results of the project will provide a better understanding of turbulence and its effect on the wind power output for the renewable energy industry, ultimately improving results and reducing costs.

Muhammed commented:

“The angle of independence is a useful measure for reducing the number of CFD simulations. Furthermore, it is important to know how fast the turbulence will recover under different circumstances. My first-year results will provide useful insights for industry enabling them to decrease the number of simulations at the design stage.”

Zenotech’s product, zCFD, has proved to be of huge benefit to the project:

“The main benefit of zCFD is its simplicity. For wind farms, it is very well-tuned with built-in input creators and a wide selection of settings. This useful tool creates input files itself along with the actuator discs. Therefore, it is suitable for iterating the simulations.

“The Zenotech support team is another great benefit. Whenever I have a problem, I send an email to David and the team, who sort it out. It is always good to have somebody to ask. Otherwise, it would be time-consuming and inefficient solving problems on my own. I could not have my results so quickly without their support. I want to say thank you to everyone at Zenotech.”

The study group was financially supported by the Uncertainty Quantification and Management in High Value Manufacturing special interest group (now Uncertainty Quantification and Management SIG of the Knowledge Transfer Network) and the School of Engineering at the University of Warwick. Acknowledgements should also go to the Republic of Turkey Ministries of National Education, Energy and Natural Resources, which fund Muhammed’s PhD studies.

To discuss a collaborative research project or to find out more about how your business or academic institution can use our tools, do get in touch.